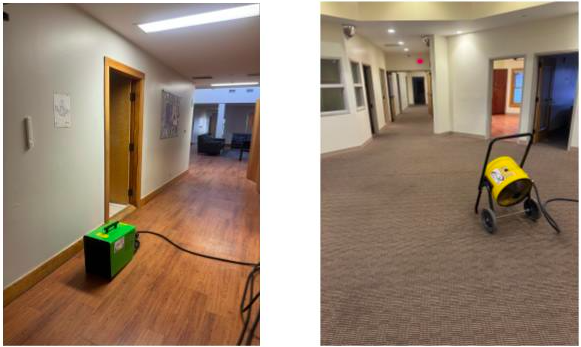

When the winter of 2025 sent temperatures plummeting, property managers faced a familiar, high-stakes nightmare: the threat of frozen pipes. In a vacant building, where there is no residual warmth from daily activity, the descent into the "danger zone" happens rapidly. To combat this, the strategic deployment of electric heater rentals—like the Porta-Air units seen in these recent site photos—becomes the primary line of defense against catastrophic water damage. However, effectively heating a large, empty commercial space isn’t as simple as plugging in a space heater from a local hardware store. It requires an understanding of electrical capacity and the fundamental differences between electric and gas-fired heat.

The Power of Voltage: Why 120V Isn´t Enough

In the first image, you’ll notice the heavy-duty cabling required to power the green Porta-Air unit. This isn´t your standard extension cord. For industrial freeze protection, voltage is everything.

The heating output of an electric heater is directly tied to its wattage, which is a product of voltage and amperage. A standard 120V outlet can typically only support a 1.5kW heater—barely enough to warm a small bedroom. To protect a sprawling office complex or hallway, you need the "heavy hitters": 208V, 240V, or even 480V three-phase units.

- · Heat Density: Higher voltage allows the unit to draw more power safely, generating the high BTU (British Thermal Units) necessary to counteract the constant heat loss through exterior walls and windows.

- · Efficiency in Scale: High-voltage units can push heat further and maintain a consistent "thermal envelope" across large square footages that lower-voltage units simply cannot reach.

Electric vs. Gas: Understanding the BTU Gap

It is a common misconception that a heater is a heater, regardless of the fuel source. In reality, the heating output of an electric heater is not equivalent to a gas-fired appliance of the same size.

Gas heaters (like propane or natural gas torpedo heaters) produce a massive amount of "instant" heat through combustion. However, they also introduce moisture and carbon monoxide into the space, making them dangerous or unsuitable for indoor use without extensive ventilation.

Electric heat, while cleaner and safer for enclosed vacant spaces, requires more "raw power" to match that output. Because electric heat is 100% efficient (converting every bit of energy into heat), you must ensure your electrical infrastructure can handle the load. Without the proper voltage, an electric heater is essentially bringing a knife to a gunfight against a sub-zero winter.

Why Electric Heat is a Winter Necessity

In a vacant building scenario, temporary electric heat is often the only viable choice for several reasons:

- Safety First: Without a resident or manager on-site 24/7, gas-fired units pose a significant fire and explosion risk. Electric units provide a "set it and forget it" level of reliability.

- Dry Heat: Unlike combustion heat, which releases water vapor, electric heat provides dry warmth. This is crucial for preventing mold growth in stagnant, vacant environments.

- Targeted Placement: As seen in the second image with the yellow high-velocity fan heater, these units can be positioned specifically near "wet" walls or utility rooms where pipe runs are most vulnerable.

Conclusion

As we look back at the winter of 2025, the buildings that remained dry and undamaged were those that didn´t cut corners on their heating strategy. Investing in professional-grade, high-voltage electric heating is more than just a utility cost—it is an insurance policy against the devastating costs of a burst pipe and a flooded facility.

(888) 519-1422

(888) 519-1422  FREE Spec-Out Request

FREE Spec-Out Request Rental Emergency 24/7

Rental Emergency 24/7